SCU provides EV chargers for three charging stations in the Wuhai Mining Area, Inner Mongolia, with a total of 9 EV charging stacks and more than 70 charging terminals to charge electric heavy trucks in the mining area. SCU’s EV charger can realize intelligent charging, support two guns charge one truck at the same time, and automatically cut off the power when fully charged, improving charging efficiency while ensuring safety.

Learn more

SCU provides a 2MWh 40ft energy storage container system and a 1500kvA UPS for a gemstone mine in Mozambique to ensure the stability of power supply, improve energy efficiency, reduce costs and carbon emissions, and achieve green development.

Learn more

SCU provides German customers with an integrated solar energy storage EV charging system, which can reduce the pressure on the power grid and help users save energy costs significantly. The intelligent management system can monitor and optimize energy use in real-time to ensure the efficient operation of the entire system.

Learn more

SCU has provided more than 20 units of 180kw EV chargers for bus station projects in multiple cities in Italy, charging more than 60 city buses, ensuring that the vehicles can quickly restore power in a short time, improving the operational efficiency of the buses and ensuring their normal operation around the clock.

Learn more

SCU provides a Hungarian stadium with an energy storage system (GRES), helping the stadium optimize the use of electricity for high-energy-consuming equipment such as lighting, improve energy efficiency, and promote local energy sustainable development.

Learn more

SCU energy storage container has been successfully applied to a pig farm in Belgium, helping to achieve solar consumption and peak-valley arbitrage, helping customers maximize energy utilization, reduce operating costs, and promote the farm’s sustainable development.

Learn more

SCU provides the Hungarian pencil factory with the GRES energy storage system, which uses peak-shaving arbitrage in electricity prices to help the company optimize and manage energy and reduce carbon emissions.

Learn more

SCU provides a PV-distributed energy storage solution for a chicken farm in Belgium, using a 20ft energy storage container to ensure the normal operation of the chicken farm’s mechanical equipment, reduce adverse effects, and achieve green agriculture.

Learn more

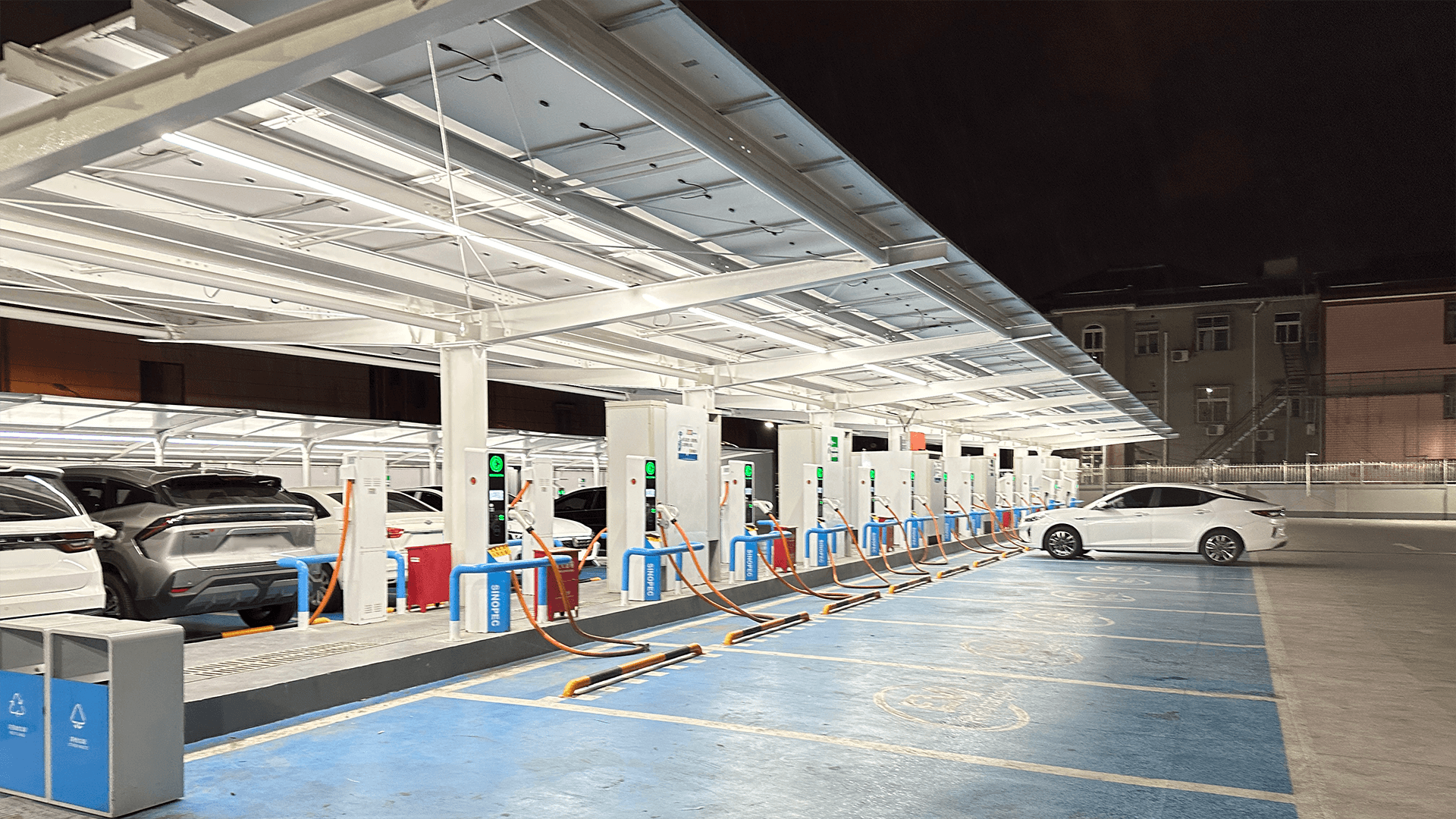

SCU provides more than 100 sets of distributed EV chargers and dual-gun EV chargers for a SINOPEC gas station in Zhejiang, providing efficient charging services for electric vehicles and becoming an important part of promoting local new energy applications.

Learn moreSCU's website uses cookies. By staying here you are agreeing to our use of cookies.

Learn more I AGREE